"I only greased you up 6k miles ago" was also a a pollite version of what else was said.

Anyhoo, having looked at how the pins of mild steel had rotted, I decided my plans of two years ago some people may remember, was to make some stainless steel pins.

Some 303 3/16" was ordered and the following pins made:

I initially attacked the offside calliper (closest to house light if evening approached) and drilled down the centre of the pin with a 2mm drill, once half way through and enough to break the portion off and get one pad out, I proceeded to further increase the drill bit by 0.5mm increments until the full 4.5mm pad pin diameter had been reached.

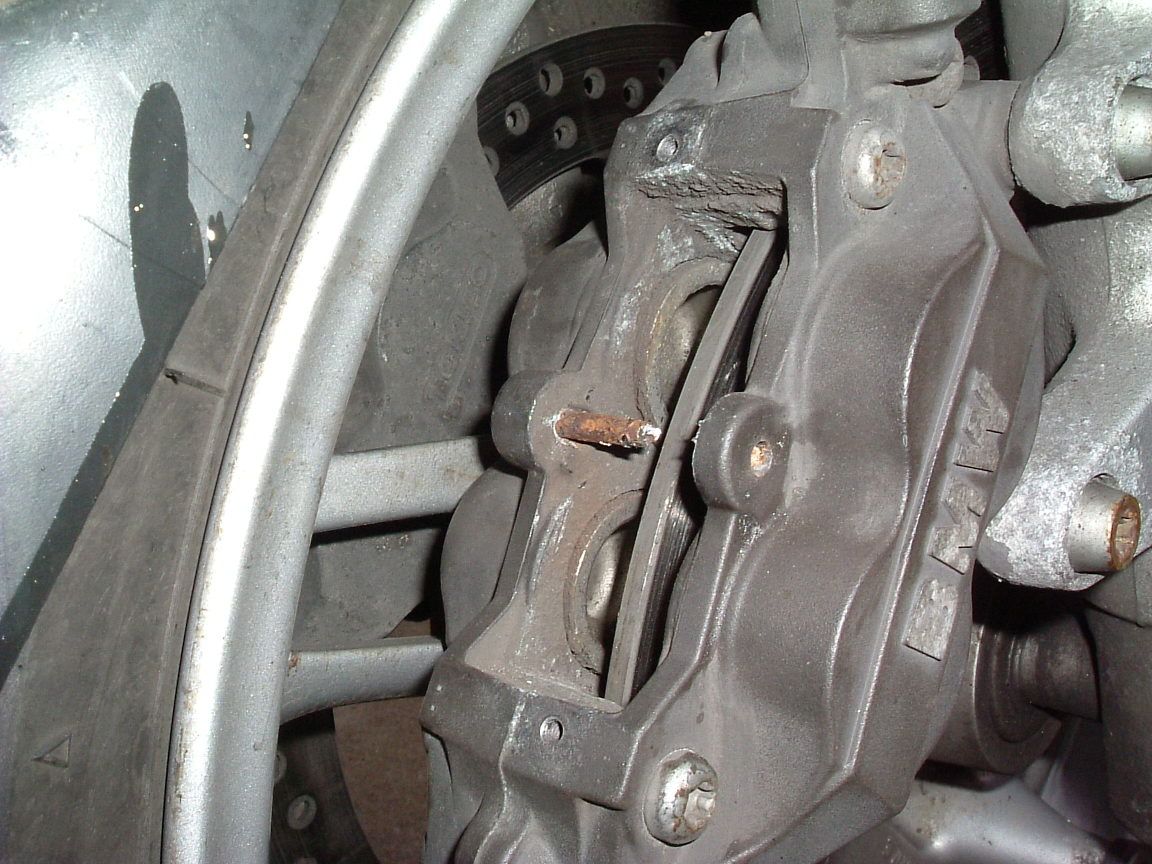

I took the calliper off the stancion, broke the first portion off and got the pads out after pushing the pistons back in, I was then left with the nasty position as such:

After going around my neighbours and borrowing some pliars (broke mine), I got the pin out after wagging it back and forth gently:

OK, going to go now clean the first calliper, fit the replacement pads and pin, then set forth on the second calliper, wish me luck